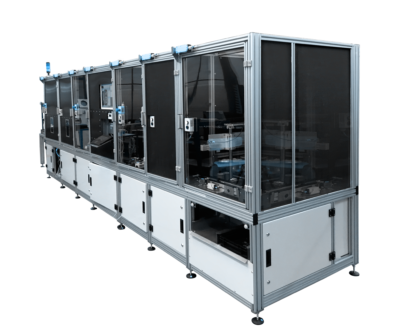

The new automatic machine is used to mark and finalize up to 120 types and variants of LED modules. For first the assembled LED module is welded by ultrasound, then is marked by fiber laser and the accuracy and quality of the label is checked by the camera. In the next step, two automatic screwdrivers unscrew the clamps. Using a multimeter is checked the electric current flow and the luminosity of the LED module. The LED module is then printed in color, checked by the camera, described by the laser from the other side, and again checked by the camera to ensure fault-free output.

AKTUELLE

AKTUELLE

Die Welt der Technik verändert sich ständig, entwickelt sich weiter und bringt neue Herausforderungen mit sich. Wir behalten den Überblick, um originelle Ideen einzubringen und die effektivsten Lösungen für Ihr Projekt zu finden.