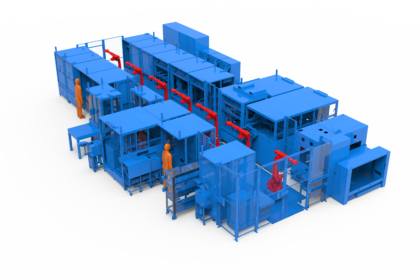

The new automatic assembly control line will complete and test car displays. In the first phase, “blisters” are inserted into the line with components, from which the display is gradually assembled and then checked. The line is operated by two operators, one of them connects the flat wires from the display to the PCB. The second operator performs a visual inspection and removes the finished products from the line. All other manipulations are then secured by Kuka robots.

NEWS

NEWS

The world of technology is constantly changing, developing and bringing new challenges. We stay on top of it to bring original ideas and find the most effective solutions for your project.