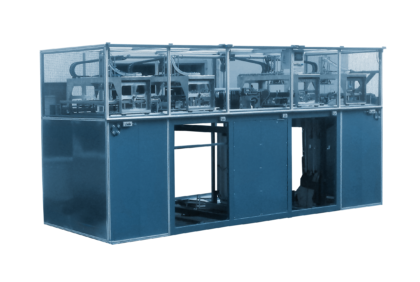

We supplied another new automatic line for heat exchanger cores folding. The input material is aluminum slats, which enter the machine on special handling pallets of our construction. The lamellas are subsequently removed by a low-pressure vacuum gripper, inspected and joined by bending. The low vacuum for handling is not developed by conventional vacuum pumps or ejectors, but by the unique low-pressure high-flow exhaust system that we developed based on our research on thin material handling. An interesting feature is the folding mechanism, which uses a cam mechanism and a servomotor instead of classic pneumatic cylinders. The machine operates in 24/7 mode and consists of different core plans. Adjustment of the machine to another dimension is done automatically by servomotors and pneumatic movements. The operator is only invited to exchange input materials.

NEWS

NEWS

The world of technology is constantly changing, developing and bringing new challenges. We stay on top of it to bring original ideas and find the most effective solutions for your project.