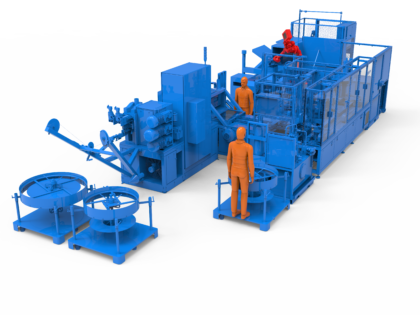

The automatic line is used for cold rolling of wires at a speed of up to 4 m / s and their subsequent processing by cutting into brushes. The line consists of several stations. There is a gradual hydraulic bending of the sheet metal envelope and then assembly with a bundle of wire and brush shape calibration. The line is equipped with an air-conditioned overpressure switchboard and other elements that enable long-term operation in an environment with airborne steel dust. There is also included a robotic workstation with a Yaskawa GP50 robot with a gripper for gripping and trimming wire ends.

NEWS

NEWS

The world of technology is constantly changing, developing and bringing new challenges. We stay on top of it to bring original ideas and find the most effective solutions for your project.