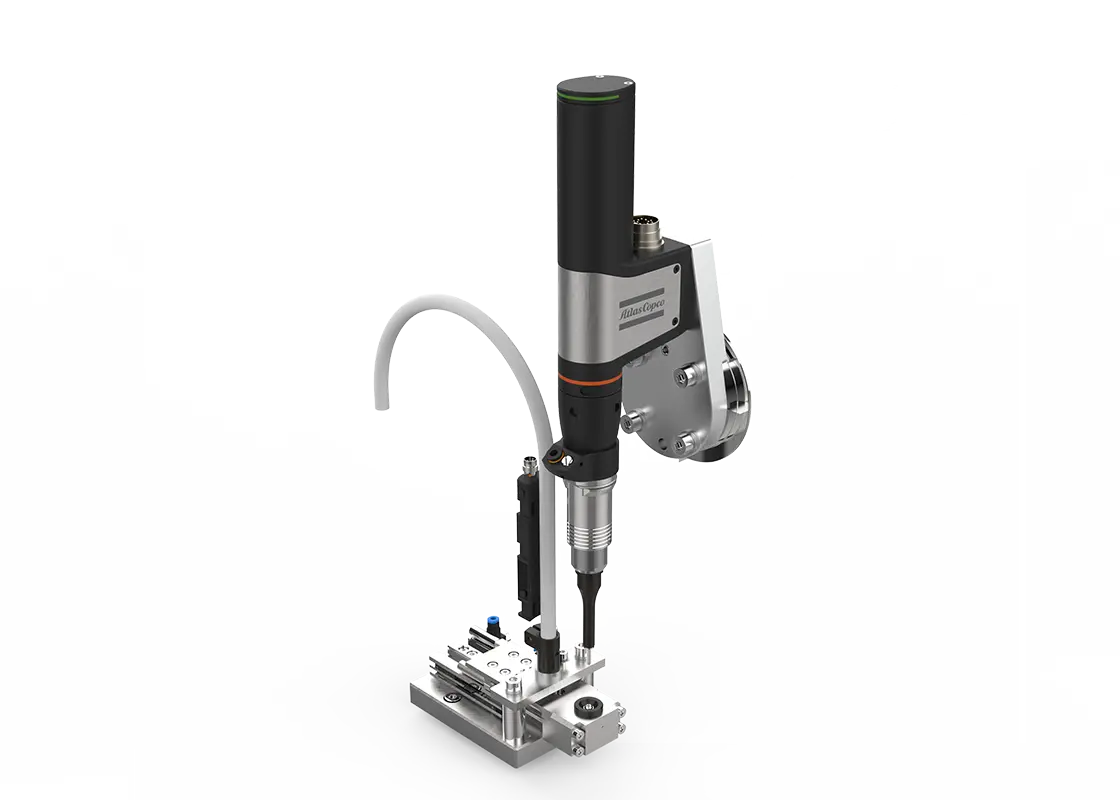

Pick and Place

A simple and elegant solution for cases where there is not enough space above the screw or the screw is not suitable for feeding by hose.

When using a vacuum nose, there is no magnetization of the part and all dirt or dust is sucked out and trapped in the air filter. The magnetic bit option is a reliable and economical alternative for cases where a magnetized part is not a concern.

Principle of function

The screws are shot into the picking station from which a screwdriving spindle fitted with a magnetic bit or vacuum nose removes them. It then moves to the screwdriving position where the actual screwing takes place.

For screws that are not suitable for hose-assisted injection due to their shape, the screws can be removed by vacuum nose directly from the feeder.

Key features

Screwing into hard to reach places

Solution for square screws

Possibility of magnetic attachment

Simple and reliable solution

Contact us

|

Sales department |

"The key to success is listening to the needs of the customer and building strong partnerships. Together we can find the best solutions and achieve great results." |