Technology

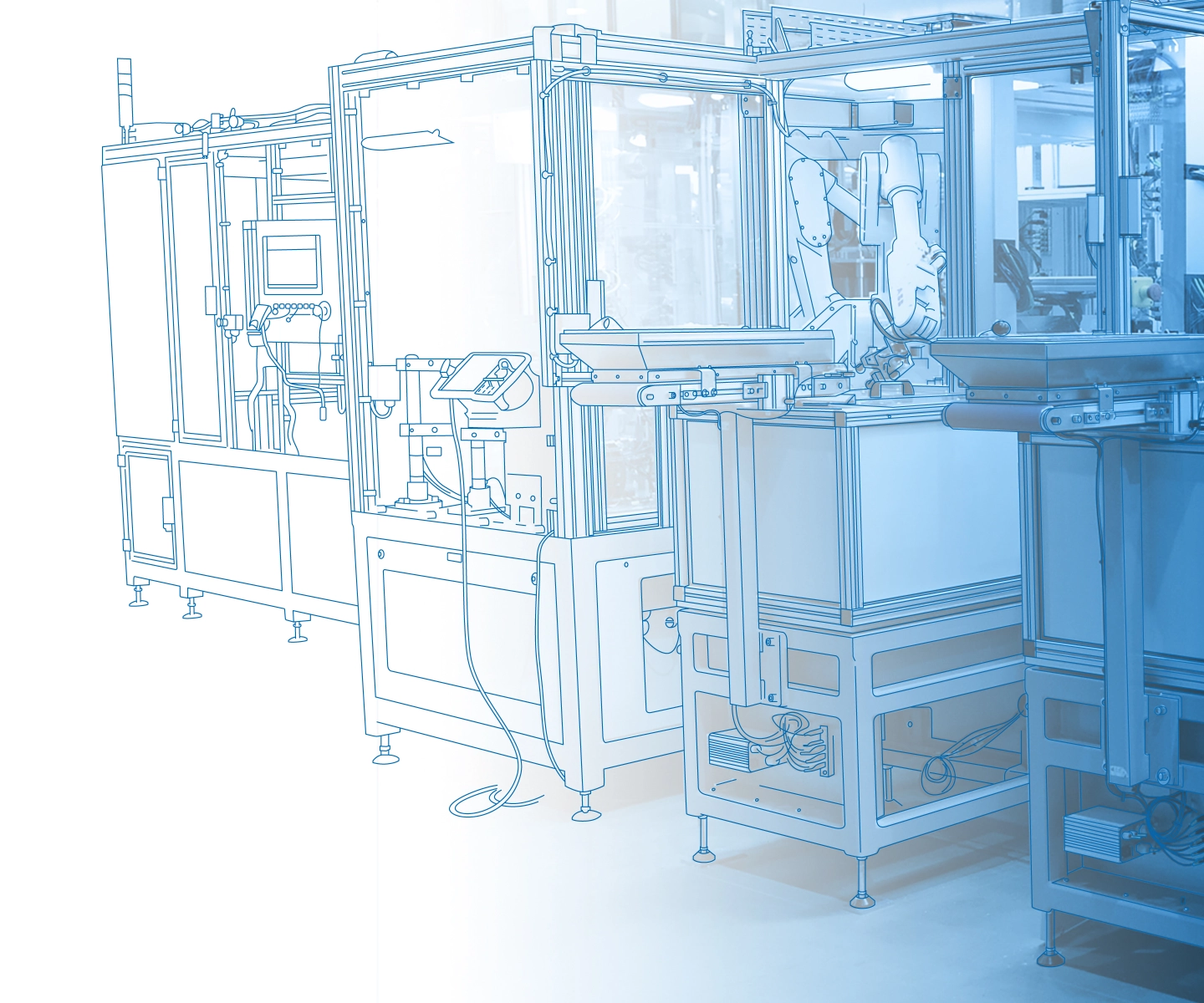

We are a technology company. Mechanical engineers with extensive experience in the production of automated and robotic lines for various industries. Our goal is to provide cutting-edge solutions with an emphasis on quality and reliability.

Over the decades of operation since 1999, we have acquired extensive know-how thanks to a large number of customer projects and requirements, which has pushed our production constantly forward.

From classic assembly processes such as feeding, joining, cutting, welding and testing, to marking, batching and robot integration and testing.

Get an overview of our capabilities, technologies that are part of our production lines.

Assembly technology

Screwdriving

This process involves the use of automated and manual screwdriving systems with high precision and efficiency, ideally in combination with our feeding systems.

Parts feeding

Automated parts feeding is key to an efficient production process. We use various types of feeders, including step feeders, bowl feeders and tray feeders, to ensure a smooth and accurate flow of screws and other components to the production line.

Marking

Marking is essential for product identification and traceability. We offer a wide range of technologies such as tampo print, laser marking, inkjet, micro punch and label application to enable clear and permanent product marking.

Pressing

Pressing is the process of forming materials using pressure. We use servo presses, hydraulic and pneumatic presses that provide high precision and repeatability, which is key to producing parts with precise dimensions and shapes.

Dispensing

Dispensing involves the precise application of lubricants, sealants and other materials to products. This process is important to ensure the proper function and longevity of products, and also includes bonding and coating of various materials.

Riveting

Riveting is a technique for joining parts using rivets. Our automated riveting systems ensure strong and durable joints, ideal for applications where high strength and reliability are required.

EOL testers

Robots

We integrate robotic arms from leading manufacturers such as Stäubli, KUKA, Fanuc and ABB into our production lines. The robots perform a wide range of tasks, from simple handling to complex assembly processes, increasing efficiency and reducing costs.

Welding

Welding is a key process for joining materials. We offer a variety of technologies including laser and waste welding to ensure strong and permanent joints with high precision and minimal thermal impact on the surrounding material.

Camera inspection

We use advanced optical camera inspection systems that include 3D scanning and the use of cameras for product inspection and quality control. These systems ensure that every product meets the required specifications and quality standards.

Production technology

Mechanical testing

Final mechanical tests are key to ensuring the quality and reliability of our products. We perform various types of tests such as leak tests, pressure tests, functional tests, torque force measurements, electrical tests, calibrations and a data recording program to ensure that each product is ready for use.

CNC machining

CNC machining involves various techniques for removing material to achieve desired shapes and surfaces. We use modern machine tools that ensure high precision and quality of the manufactured parts.

Other technologies

We also offer other specialised technologies and services according to the individual needs of our customers. Our flexibility and ability to adapt to specific requirements allows us to provide tailored solutions.