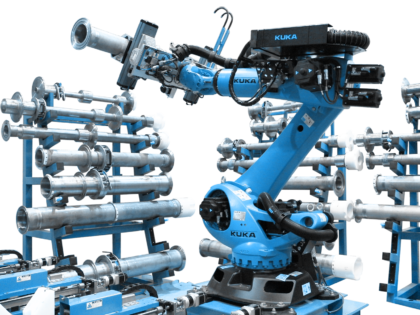

This building consists of two floors and it´s shape should look like the head and body of a dog, the material should remind the spaceship from future. Space in Cyberdog is divided into a robotic workstation, a trolleys and their rails located above visitor´s seatings, and a projection area where are projected presentations of the world technologies. If a visitor installs an app, he or she can command the robotic system to process it. The KUKA robotic arm then grabs the selected wine (or another beverage), uncork, pours a precisely measured quantity, put the bottle back and places the prepared beverage on a trolley, on which it is transported to the right table.